在化纤生产及其他高分子材料应用领域,精准的压力测量一直是行业的核心需求。传统高温熔体压力传感器常因高温导致的零点漂移而测量失准,给生产过程带来诸多困扰。而今,GRAEFF(格拉夫)推出的GAIM系列产品,凭借其创新的温度补偿技术,完美解决了这一难题,为高温压力测量带来了革命性的变革。(注:文中部分图片来源于网络,侵删)

In the fields of chemical fiber production and other polymer material applications, precise pressure measurement has always been the core demand of the industry. Traditional high-temperature melt pressure sensors often have inaccurate measurements due to zero drift caused by high temperatures, which brings many troubles to the production process. Nowadays, the GAIM series of products launched by GRAEFF (Graff) has perfectly solved this problem with its innovative temperature compensation technology, bringing a revolutionary change to high-temperature pressure measurement. (Note: Some of the pictures in this article are from the Internet. If there is any infringement, please delete them.)

一、产品简介

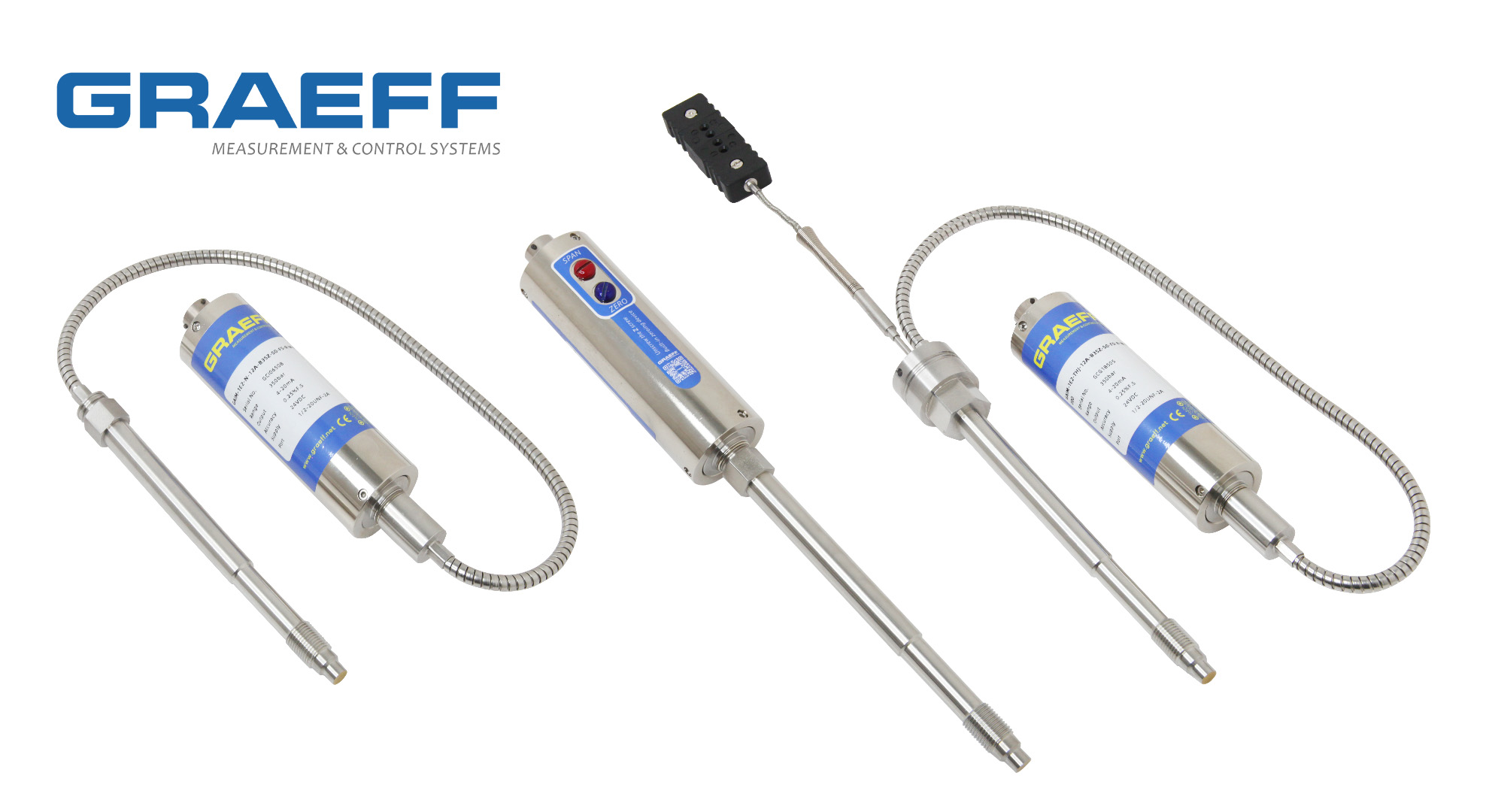

GAIM系列熔体压力传感器/变送器是GRAEFF(格拉夫)专为高温环境设计的高端产品。传统传感器在从室温升温至高温的过程中,传感器零点会因高温影响产生较大漂移,导致测量偏差。GAIM系列产品采用先进的温度补偿技术,在350℃下进行零点漂移补偿,使得压力测量探头在高温下接近零温漂,极大地提高了测量的准确性和稳定性。

Product Introduction

The GAIM series melt pressure sensors/transmitters are high-end products designed by GRAEFF specifically for high-temperature environments. During the process of heating from room temperature to high temperature, the zero point of traditional sensors will drift significantly due to the influence of high temperature, resulting in measurement deviation. The GAIM series products adopt advanced temperature compensation technology and perform zero drift compensation at 350℃, enabling the pressure measurement probe to approach zero temperature drift at high temperatures and significantly enhancing the accuracy and stability of the measurement.

二、产品优势

1. 零温漂技术:在高温环境下,GAIM系列传感器通过温度补偿技术,有效消除了传统传感器的零点漂移问题,确保测量数据的精准可靠。

2. 高精度测量:GAIM系列熔体压力传感器采用了高性能的核心元件,并经过严格的质量控制和校准流程,确保了测量的高精度。其准确度可达±0.25% FSO,可重复性为±0.1% FSO,能够为用户提供精确可靠的压力测量数据,满足对精度要求极高的应用场景。

3. 多种信号输出:GAIM系列熔体压力传感器提供了多种输出信号选项,包括4-20mA、0-5V、0-10V以及3.33mV/V等,能够满足不同用户和不同设备的接口需求,方便与各种自动化控制系统进行集成,实现对生产过程的实时监控和自动化控制。

4. 耐高温性能:该系列产品能够承受高达400℃的高温,膜片处随温度变化的零点偏差小于0.5 bar/100°C,即使在极端的高温环境下也能保持稳定的测量性能,无需担心因温度升高而导致测量误差增大,为高温工业生产提供了可靠的测量保障。

5.丰富的尺寸选择:为了适应不同的应用场景,GAIM系列熔体压力传感器提供了多种螺纹规格、刚性杆和柔性管的长度尺寸可供选择。用户可以根据实际设备的安装空间和工艺要求,选择合适的安装方式和尺寸,确保传感器能够准确地安装在测量位置,实现最佳的测量效果。

6.可靠的电气连接与防护:可采用标准的6针航空插件进行电气连接,连接牢固可靠,同时具备良好的屏蔽性能,能够有效防止电磁干扰对测量信号的影响。其电气环境温度范围为-20℃至85℃,防护等级达到IP65,能够在恶劣的工业环境中稳定工作,确保测量信号的稳定传输和设备的安全运行。

Product advantages

1. Zero temperature drift technology: In high-temperature environments, the GAIM series sensors effectively eliminate the zero drift problem of traditional sensors through temperature compensation technology, ensuring the accuracy and reliability of measurement data.

2. High-precision measurement: The GAIM series melt pressure sensors adopt high-performance core components and undergo strict quality control and calibration processes to ensure high-precision measurement. Its accuracy can reach ±0.25% FSO, and its repeatability is ±0.1% FSO. It can provide users with precise and reliable pressure measurement data, meeting the application scenarios with extremely high precision requirements.

3. Multiple signal outputs: The GAIM series melt pressure sensors offer a variety of output signal options, including 4-20mA, 0-5V, 0-10V, and 3.33mV/V, etc. They can meet the interface requirements of different users and devices, facilitate integration with various automatic control systems, and achieve real-time monitoring and automatic control of the production process.

4. High-temperature resistance: This series of products can withstand temperatures up to 400 ° C. The zero point deviation at the diaphragm with temperature changes is less than 0.5 bar/100° C. Even in extreme high-temperature environments, it can maintain stable measurement performance, eliminating the need to worry about increased measurement errors due to rising temperatures. It provides reliable measurement guarantees for high-temperature industrial production.

5. Rich size options: To adapt to different application scenarios, the GAIM series melt pressure sensors offer a variety of thread specifications, as well as length sizes for rigid rods and flexible tubes to choose from. Users can select the appropriate installation method and size based on the actual installation space of the equipment and the process requirements to ensure that the sensor can be accurately installed at the measurement position and achieve the best measurement effect.

6. Reliable electrical connection and protection: Standard 6-pin aviation plugs can be used for electrical connection, which is firm and reliable. At the same time, it has good shielding performance and can effectively prevent the influence of electromagnetic interference on the measurement signal. Its electrical ambient temperature range is from -20℃ to 85℃, and its protection level reaches IP65. It can operate stably in harsh industrial environments, ensuring the stable transmission of measurement signals and the safe operation of the equipment.

三、应用领域

化纤行业

在化纤生产过程中,熔融状态下的纤维压力监测至关重要。GAIM系列熔体压力传感器能够精准地监测熔融纤维的压力,确保纺丝过程的稳定性和纤维质量的一致性。通过精确控制压力,可以有效避免因压力波动导致的纤维断裂、粗细不均等问题,从而提高纤维的品质和生产效率。此外,GAIM系列熔体压力传感器的耐高温性能和高精度测量能力使其能够在化纤行业的高温环境下长期稳定运行,为化纤生产提供可靠的测量保障。

Application field

Chemical fiber industry

In the process of chemical fiber production, the monitoring of fiber pressure in the molten state is of vital importance. The GAIM series melt pressure sensors can precisely monitor the pressure of molten fibers, ensuring the stability of the spinning process and the consistency of fiber quality. By precisely controlling the pressure, problems such as fiber breakage and uneven thickness caused by pressure fluctuations can be effectively avoided, thereby improving the quality of fibers and production efficiency. In addition, the high-temperature resistance and high-precision measurement capabilities of the GAIM series melt pressure sensors enable them to operate stably for a long time in the high-temperature environment of the chemical fiber industry, providing reliable measurement support for chemical fiber production.

化工行业

化工行业中存在大量的高温反应和物料输送过程,这些过程中的压力控制对于安全生产和产品质量起着决定性作用。GAIM系列熔体压力传感器适用于多种化工介质的压力测量,包括高温液体、气体以及具有腐蚀性的介质。其高性能的膜片材质和可靠的密封设计,能够抵御化工介质的侵蚀,确保传感器在恶劣的化工环境中长期稳定运行。通过精确测量反应釜、管道等设备内的压力,为化工生产过程的自动化控制提供准确的数据支持,有效预防因压力异常导致的安全事故,保障化工生产的顺利进行。

Chemical industry

There are a large number of high-temperature reactions and material transportation processes in the chemical industry. The pressure control in these processes plays a decisive role in safe production and product quality. The GAIM series melt pressure sensors are suitable for pressure measurement of various chemical media, including high-temperature liquids, gases, and corrosive media. Its high-performance diaphragm material and reliable sealing design can resist the erosion of chemical media, ensuring the long-term stable operation of the sensor in harsh chemical environments. By precisely measuring the pressure inside equipment such as reaction vessels and pipelines, accurate data support is provided for the automatic control of the chemical production process, effectively preventing safety accidents caused by abnormal pressure and ensuring the smooth progress of chemical production.

高分子材料生产

在高分子材料的生产过程中,无论是聚合反应阶段对反应釜内压力的精准监控,还是挤出成型环节对熔体压力的实时测量,都需要高度可靠的传感器来保障生产的安全与效率。GAIM系列熔体压力传感器以其卓越的抗高温零点漂移性能,能够精确监测熔体在高温下的压力变化,确保生产过程的稳定性和产品质量的一致性。通过精确控制压力,可以有效避免因压力波动导致的产品缺陷,如气泡、裂纹等,从而提高产品的合格率和市场竞争力。

Production of polymer materials

In the production process of polymer materials, whether it is the precise monitoring of the pressure inside the reactor during the polymerization reaction stage or the real-time measurement of the melt pressure during the extrusion molding stage, highly reliable sensors are needed to ensure the safety and efficiency of production. The GAIM series melt pressure sensors, with their outstanding anti-high-temperature zero drift performance, can precisely monitor the pressure changes of the melt at high temperatures, ensuring the stability of the production process and the consistency of product quality. By precisely controlling the pressure, product defects caused by pressure fluctuations, such as bubbles and cracks, can be effectively avoided, thereby enhancing the product qualification rate and market competitiveness.

食品加工

在食品加工领域,一些高温加工工艺如食品的高温杀菌、烘焙等也需要对压力进行严格控制。GAIM系列传感器可以应用于食品加工设备中的压力监测,确保加工过程符合工艺要求,保障食品的质量和安全。例如,在饮料的高温灌装过程中,精确的压力控制可以防止瓶子破裂和饮料泄漏,同时保证产品的密封性和保质期。在食品烘焙过程中,对烤箱内的压力进行监测可以优化烘焙效果,使食品口感更佳。

Food processing

In the field of food processing, some high-temperature processing techniques such as high-temperature sterilization and baking of food also require strict control of pressure. The GAIM series sensors can be applied to pressure monitoring in food processing equipment to ensure that the processing process meets the technological requirements and guarantees the quality and safety of food. For instance, during the high-temperature filling process of beverages, precise pressure control can prevent bottle breakage and beverage leakage, while ensuring the product's sealing performance and shelf life. During the food baking process, monitoring the pressure inside the oven can optimize the baking effect and make the food taste better.

其他领域

GAIM系列传感器还广泛应用于石油化工、航空航天、制药等多个领域,为各种高温高压环境下的压力监测提供可靠的解决方案。

Other fields

The GAIM series sensors are also widely used in multiple fields such as petrochemicals, aerospace, and pharmaceuticals, providing reliable solutions for pressure monitoring in various high-temperature and high-pressure environments.

四、专业服务,助力客户成功应用

在产品选型阶段,GRAEFF(格拉夫)的技术团队会根据客户的工艺要求和测量条件,为客户提供专业的选型建议,帮助客户选择最适合的产品。在安装调试过程中,我们提供详细的操作说明书和专业的技术支持,确保传感器能够正确安装和调试,快速投入使用。如果客户在使用过程中遇到任何问题,我们的售后服务团队将随时提供及时、有效的技术支持和解决方案,确保客户的生产过程不受影响。

GRAEFF(格拉夫)GAIM系列熔体压力传感器/变送器以其卓越的零温漂技术、高精度测量能力和广泛的适用性,成为了高温压力测量领域的理想选择。无论是在塑料挤出、化工、食品饮料还是其他领域的应用中,GAIM系列熔体压力传感器都能提供稳定可靠的测量数据,助力企业提升生产效率和产品质量。选择GAIM系列,就是选择精准、稳定和高效。

Professional services to help customers successfully apply

During the product selection stage, GRAEFF's technical team will provide professional selection suggestions based on the customer's process requirements and measurement conditions, helping the customer choose the most suitable product. During the installation and commissioning process, we provide detailed operation manuals and professional technical support to ensure that the sensors can be correctly installed and debugged and put into use quickly. If customers encounter any problems during the usage process, our after-sales service team will provide timely and effective technical support and solutions at any time to ensure that the production process of customers is not affected.

The GRAEFF (Graf) GAIM series melt pressure sensors/transmitters, with their outstanding zero temperature drift technology, high-precision measurement capabilities and wide applicability, have become the ideal choice in the field of high-temperature pressure measurement. Whether in applications such as plastic extrusion, chemical engineering, food and beverage, or other fields, the GAIM series melt pressure sensors can provide stable and reliable measurement data, helping enterprises improve production efficiency and product quality. Choosing the GAIM series means choosing precision, stability and efficiency.