一、产品简介Product Introduction

GINS系列熔体压力传感器/变送器是由英国GRAEFF控股子公司GRAEFF中国公司团队精心研发制造的高性能测量设备。该产品主体采用高品质不锈钢材质,其他关键部件则通过特殊工艺制造,并经过严格的高强度测试,确保了产品的卓越耐用性和可靠性。传感器的膜片部分应用了先进的钛化合物特殊涂层技术,使其能够有效抵御黏度和摩擦性较大物质的侵蚀,显著延长了使用寿命。凭借NTX环保合金介质填充技术,GINS系列熔体压力传感器测量性能精确、受温度漂移影响小且稳定性高,可广泛应用于食品和制药领域等对卫生标准要求严苛的行业。

在技术规格方面,GINS系列产品支持多种输出信号,涵盖3.33mV/V、4-20mA、0-5V、0-10V等,同时具备温度和压力双测量功能,能够充分满足不同塑料挤出设备以及各类工业应用场景的多样化需求。其高达350摄氏度的耐温设计,确保了在极端高温条件下的稳定性和可靠性,为工业生产中的高温加工过程提供了可靠保障。精准的信号输出功能则为压力监控奠定了坚实基础,使操作人员能够实时掌握生产过程中的压力变化情况。

此外,该传感器还具备设备保护功能,可在设备出现过载或其他异常情况时及时发出警报,有效保护设备免受损害,可延长设备使用寿命,降低企业的设备维护成本和停机风险。

The GINS series melt pressure sensor/transmitter is a high-performance measurement device meticulously developed and manufactured by the team of GRAEFF China, a subsidiary of GRAEFF in the UK. The main body of this product is made of high-quality stainless steel, while other key components are manufactured through special processes and undergo strict high-intensity tests, ensuring the product's outstanding durability and reliability. The diaphragm part of the sensor is coated with advanced titanium compound special coating technology, which enables it to effectively resist the erosion of substances with high viscosity and friction, significantly extending its service life. With the NTX environmentally friendly alloy medium filling technology, the GINS series sensors not only have precise measurement performance, are less affected by temperature drift and have high stability, but also can be widely applied in industries with strict hygiene standards such as food and pharmaceuticals.

In terms of technical specifications, the GINS series sensors support multiple output signals, covering 3.33mV/V, 4-20mA, 0-5V, 0-10V, etc. They also have dual measurement functions for temperature and pressure, fully meeting the diverse needs of different plastic extrusion equipment and various industrial application scenarios. Its high-temperature resistance design up to 350 degrees Celsius ensures stability and reliability under extreme high-temperature conditions, providing a reliable guarantee for high-temperature processing in industrial production. The precise signal output function lays a solid foundation for pressure monitoring, enabling operators to grasp the pressure changes during the production process in real time.

In addition, this sensor also features equipment protection capabilities. It can promptly issue an alarm when the equipment experiences overload or other abnormal conditions, effectively safeguarding the equipment from damage. This can extend the service life of the equipment, reduce the equipment maintenance costs and downtime risks for enterprises.

二、产品优势Product advantages

(一)高精度测量High-precision measurement

核心元件优势:采用高性能核心元件,确保了测量的高精度和稳定性,为工业生产中的精确控制提供了可靠的数据支持。

模拟电路设计:配备抗干扰性更强的模拟电路设计,使其能够在复杂的工业环境中保持准确的测量,有效避免因电磁干扰等因素导致的测量误差,保障测量数据的准确性和可靠性。

精度指标:可获得±0.5% FSO的高测量精度,这一高精度水平能够满足工业生产对精确测量的严格要求,有助于提高产品质量的一致性和生产过程的稳定性。

Core component advantages: The adoption of high-performance core components ensures high precision and stability in measurement, providing reliable data support for precise control in industrial production.

Analog circuit design: Equipped with a more anti-interference analog circuit design, it can maintain accurate measurement in complex industrial environments, effectively avoid measurement errors caused by factors such as electromagnetic interference, and ensure the accuracy and reliability of measurement data.

Accuracy index: A high measurement accuracy of ±0.5% FSO can be achieved. This high precision level can meet the strict requirements of industrial production for precise measurement, which is conducive to improving the consistency of product quality and the stability of the production process.

(二)高稳定性与可靠性High stability and reliability

材料与工艺:由高品质的不锈钢制成,其他材料也通过特殊工艺制造,并经过高强度测试,确保了产品的耐用性和可靠性。这种高品质的材料和精湛的制造工艺使得传感器能够在恶劣的工业环境中长期稳定运行,减少了因材料老化或工艺缺陷导致的故障风险。

温度漂移小:采用NTX环保合金介质填充技术,受温度漂移的影响更小,测量结果更加稳定。这一特性对于需要长时间连续监测的工业生产过程尤为重要,能够确保测量数据的稳定性,避免因温度变化导致的测量误差,提高生产过程的可控性。

使用寿命长:妥善处理GINS系列传感器可延长使用寿命,从而降低设备维护成本和更换频率,为企业节省运营成本。其耐用的设计和高品质的材料使其能够承受工业生产中的各种严苛条件,减少了因设备故障导致的停机时间和维修成本。

Materials and Craftsmanship: Made of high-quality stainless steel, other materials are also manufactured through special processes and undergo high-intensity tests, ensuring the durability and reliability of the product. This high-quality material and exquisite manufacturing process enable the sensor to operate stably for a long time in harsh industrial environments, reducing the risk of failure caused by material aging or process defects.

Small temperature drift: The NTX environmentally friendly alloy medium filling technology is adopted, which is less affected by temperature drift and makes the measurement results more stable. This feature is particularly important for industrial production processes that require continuous monitoring for long periods of time. It can ensure the stability of measurement data, avoid measurement errors caused by temperature changes, and improve the controllability of the production process.

Long service life: Proper handling of the GINS series sensors can extend their service life, thereby reducing equipment maintenance costs and replacement frequency, and saving operating costs for enterprises. Its durable design and high-quality materials enable it to withstand various harsh conditions in industrial production, reducing downtime and maintenance costs caused by equipment failures.

(三)经济与实用的设计Economic and practical design

经济外形设计:在保证性能的同时,具有经济的外形设计,降低了客户的采购成本,提高了产品的性价比。这种设计使得企业在不降低生产质量的前提下,能够以更经济的方式实现生产过程的优化和监控,为企业的发展提供了有力支持。

易于安装与维护:安装和卸载过程简单,有详细的指导说明,确保了设备的快速安装和维护。其简洁的设计和明确的操作指南使得技术人员能够轻松地进行设备的安装、调试和维护工作,减少了安装和维护时间,提高了设备的使用效率。

Economic shape design: While ensuring performance, it features an economical shape design, reducing customers' procurement costs and enhancing the cost-effectiveness of the product. This design enables enterprises to optimize and monitor the production process in a more economical way without reducing production quality, providing strong support for the development of enterprises.

Easy to install and maintain: The installation and uninstallation process is simple, with detailed guidance and instructions, ensuring the rapid installation and maintenance of the equipment. Its simple design and clear operation guide enable technicians to easily carry out the installation, commissioning and maintenance of the equipment, reducing the installation and maintenance time and improving the utilization efficiency of the equipment.

(四)环保与安全Environmental Protection and Safety

环保材料:采用环保合金介质填充技术,符合环保要求,可应用于食品和制药领域。这一环保特性不仅有助于企业满足日益严格的环保法规要求,还能够确保在食品和制药等对卫生和环保要求极高的行业中,产品的使用不会对环境和产品质量造成不良影响。

安全设计:在设计和制造过程中充分考虑了安全性,如在加热条件下进行拆卸等操作设计,确保了操作的安全性。这种安全设计能够有效降低操作人员在设备安装、维护和使用过程中的安全风险,保障生产过程的安全稳定运行。

Environmentally friendly materials: Utilizing environmentally friendly alloy medium filling technology, it meets environmental protection requirements and can be applied in the food and pharmaceutical fields. This environmental protection feature not only helps enterprises meet increasingly strict environmental protection regulations, but also ensures that in industries with extremely high hygiene and environmental protection requirements such as food and pharmaceuticals, the use of products will not have adverse effects on the environment and product quality.

Safety design: Safety was fully considered during the design and manufacturing process, such as the design for disassembly and other operations under heating conditions, ensuring the safety of the operation. This safety design can effectively reduce the safety risks for operators during the installation, maintenance and use of equipment, ensuring the safe and stable operation of the production process.

(五)广泛的应用范围Wide range of applications

多种介质适用:适用于液态、气态或粘流状态的物质,能够满足不同工业场景的需求。无论是化工生产中的液体物料、塑料加工中的熔融塑料,还是制药行业的药用辅料等,GINS系列传感器都能够提供准确的熔体压力测量,为各类工业生产过程提供可靠的监测支持。

多领域应用:广泛应用于塑料、化纤、橡胶、食品、制药、化工、石油化工、能源工业、电站、污水处理、航海造船工业、环境工程、喷涂设备、汽车工业、工厂工程和机械工程、玻璃和纺织工业等多个领域。在塑料加工领域,它能够优化挤出和注塑工艺,提高产品质量;在化纤行业,助力纤维生产的精细化控制;在橡胶行业,保障橡胶制品的质量和性能;在食品和制药领域,满足严格的卫生标准,确保产品的安全性和质量;在工业自动化领域,实现设备的智能化监控和控制,提高生产效率和设备可靠性。

Applicable to multiple media: Suitable for substances in liquid, gaseous or viscous flow states, it can meet the needs of different industrial scenarios. Whether it is liquid materials in chemical production, molten plastics in plastic processing, or pharmaceutical excipients in the pharmaceutical industry, the GINS series sensors can provide accurate melt pressure measurement, offering reliable monitoring support for various industrial production processes.

Multi-field application: Widely used in multiple fields such as plastics, chemical fibers, rubber, food, pharmaceuticals, chemicals, petrochemicals, energy industry, power stations, sewage treatment, Marine and shipbuilding industry, environmental engineering, spraying equipment, automotive industry, factory engineering and mechanical engineering, glass and textile industry, etc. In the field of plastic processing, it can optimize extrusion and injection molding processes and improve product quality. In the chemical fiber industry, it helps to achieve precise control in fiber production. In the rubber industry, ensure the quality and performance of rubber products; In the fields of food and pharmaceuticals, meet strict hygiene standards to ensure the safety and quality of products; In the field of industrial automation, it is necessary to achieve intelligent monitoring and control of equipment to enhance production efficiency and equipment reliability.

三、应用领域Application field

(一)塑料加工领域Plastic processing field

在塑料挤出和注塑等加工工艺中,熔体压力的精准控制对于保障产品质量的稳定性起着至关重要的作用。例如,在生产塑料薄膜、管材、型材等产品时,通过精确控制熔体压力,可以有效避免产品出现厚度不均、表面瑕疵等质量问题,显著提升产品的合格率和市场竞争力。在注塑成型过程中,精准的压力监测能够确保模具填充均匀,减少产品缺陷,从而提高生产效率和产品质量。在塑料挤出机的实际应用中,GINS系列熔体压力传感器不仅能够实时监测挤出机内的压力变化,还能通过精准的数据反馈,帮助操作人员及时调整工艺参数,实现工艺优化。这不仅确保了生产过程的稳定性,还提高了产品的整体质量和生产效率。

In processing techniques such as plastic extrusion and injection molding, the precise control of melt pressure plays a crucial role in ensuring the stability of product quality. For instance, when manufacturing plastic films, pipes, profiles and other products, by precisely controlling the melt pressure, quality issues such as uneven thickness and surface defects of the products can be effectively avoided, significantly enhancing the product qualification rate and market competitiveness. During the injection molding process, precise pressure monitoring can ensure uniform mold filling, reduce product defects, and thereby enhance production efficiency and product quality. In the practical application of plastic extruders, the GINS series melt pressure sensors can not only monitor the pressure changes inside the extruder in real time, but also help operators adjust process parameters in a timely manner through precise data feedback, achieving process optimization. This not only ensures the stability of the production process, but also improves the overall quality of the products and production efficiency.

(二)橡胶行业Rubber industry

在橡胶制品的生产中,如轮胎制造、密封件生产等,熔体压力的控制同样不可或缺。GINS系列熔体压力传感器可以精确测量橡胶熔体在挤出、压延等工序中的压力变化。帮助生产人员及时发现和解决生产过程中的问题,提高橡胶制品的质量和性能。例如,在轮胎制造过程中,精准的压力监测能够确保橡胶混合物在成型过程中的均匀分布,提高轮胎的耐磨性和抓地性能,保障行车安全。

In the production of rubber products, such as tire manufacturing and seal production, the control of melt pressure is equally indispensable. The GINS series melt pressure sensor can precisely measure the pressure changes of rubber melts during extrusion, calendering and other processes. Help production personnel promptly identify and solve problems in the production process, and improve the quality and performance of rubber products. For instance, during the tire manufacturing process, precise pressure monitoring can ensure the uniform distribution of rubber mixtures during the molding process, enhance the wear resistance and grip performance of tires, and guarantee driving safety.

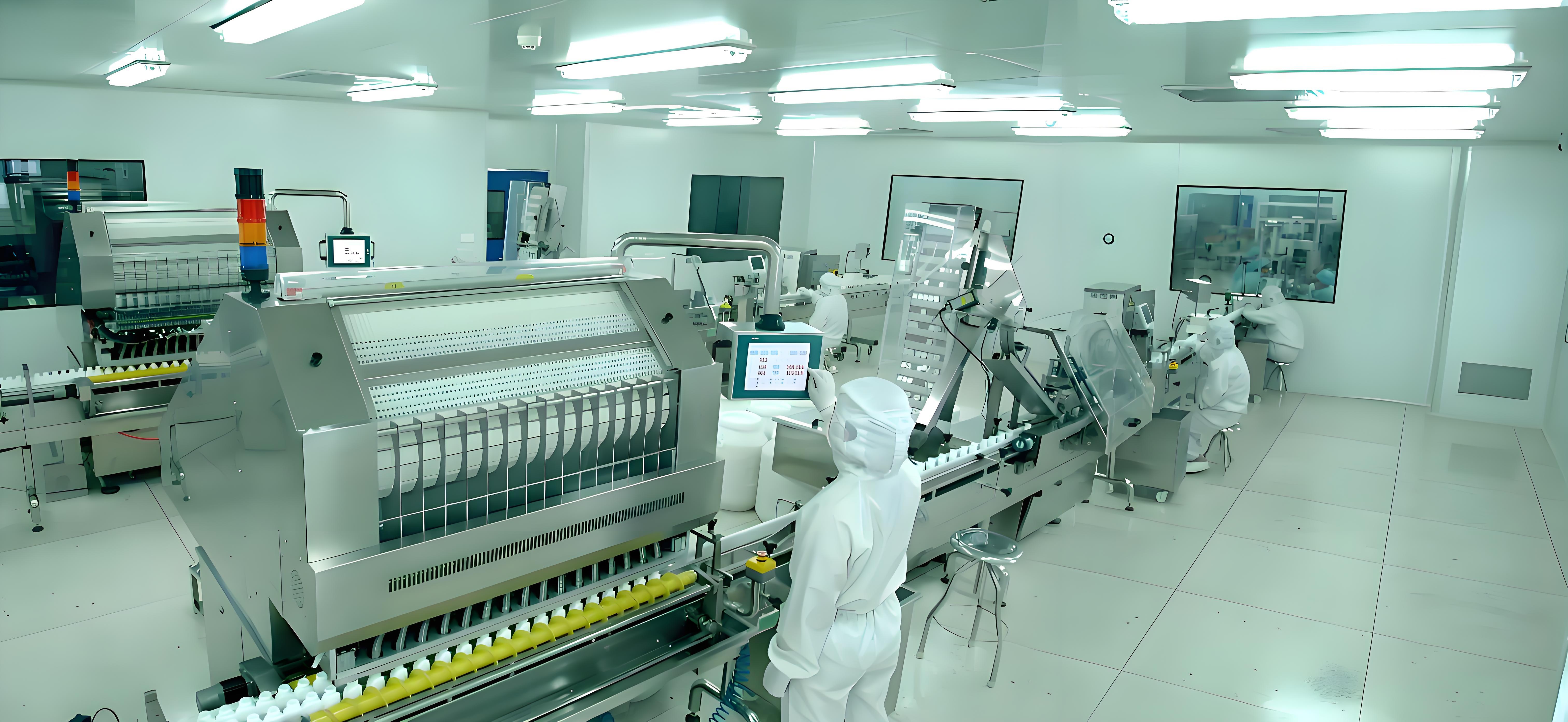

(三)食品加工领域The field of food processing

在食品包装和制药等对卫生要求极高的行业,GINS系列熔体压力传感器发挥着重要作用。该系列传感器采用NTX环保合金介质填充技术,确保了其在食品领域的适用性。这种技术不仅使传感器能够精确测量食品包装材料在加工过程中的熔体压力,还确保了产品质量符合严格的卫生标准。同时,传感器的高精度和稳定性能够满足这些行业对生产过程的严格要求,保障产品的质量和安全性。例如,在食品加工过程中,如蒸煮、烘焙、油炸等环节,需要对设备内部的压力进行精确控制。熔体压力传感器可以满足这一需求,确保食品加工的质量和安全性。在饮料灌装过程中,压力传感器用于监测灌装设备内的压力,确保灌装精度和一致性。

In industries with extremely high hygiene requirements such as food packaging and pharmaceuticals, the GINS series melt pressure sensors play a significant role. This series of sensors adopts the NTX environmentally friendly alloy medium filling technology, ensuring their applicability in the food field. This technology not only enables the sensor to precisely measure the melt pressure of food packaging materials during the processing, but also ensures that the product quality meets strict hygiene standards. Meanwhile, the high precision and stability of the sensors can meet the strict requirements of these industries for the production process, ensuring the quality and safety of the products. For instance, during food processing steps such as steaming, baking, and frying, it is necessary to precisely control the internal pressure of the equipment. Melt pressure sensors can meet this demand and ensure the quality and safety of food processing. During the beverage filling process, pressure sensors are used to monitor the pressure inside the filling equipment to ensure filling accuracy and consistency.

(四)制药行业Pharmaceutical industry

在制药生产过程中,如发酵、提取、浓缩等环节,需要对设备内部的压力进行严格控制。GINS系列熔体压力传感器可以满足制药行业对压力测量的高精度和高可靠性要求,确保药品生产的质量和安全性。在制药设备中,精准的压力监测能够保障生产过程的稳定性和一致性,避免因压力波动导致的药品质量差异,符合严格的药品生产质量管理规范(GMP)要求。此外,由于采用NTX环保合金介质填充技术,进一步增强了其在制药行业的适用性。

In the pharmaceutical production process, such as fermentation, extraction, concentration and other links, the internal pressure of the equipment needs to be strictly controlled. The GINS series melt pressure sensors can meet the high-precision and high-reliability requirements of the pharmaceutical industry for pressure measurement, ensuring the quality and safety of drug production. In pharmaceutical equipment, precise pressure monitoring can ensure the stability and consistency of the production process, avoid quality differences in drugs caused by pressure fluctuations, and meet the strict requirements of Good Manufacturing Practice (GMP) for pharmaceuticals. In addition, due to the adoption of NTX environmentally friendly alloy medium filling technology, its applicability in the pharmaceutical industry has been further enhanced.

(五)工业自动化领域The field of industrial automation

在工业自动化生产中,GINS系列熔体压力传感器被广泛应用于各类机械设备的压力监测与控制,如数控机床、自动化生产线等。通过实时监测压力参数,能够及时发现设备运行中的异常情况,从而实现预防性维护,提高设备的运行效率和可靠性。此外,这些传感器还可以与工业自动化控制系统集成,实现对生产过程的精确控制,确保产品质量的稳定性和一致性。例如,在自动化生产线中,通过监测设备的关键压力点,能够及时发现潜在的故障隐患,提前进行维护,减少设备停机时间,提高生产效率。

In industrial automated production, the GINS series melt pressure sensors are widely used in pressure monitoring and control of various mechanical equipment, such as CNC machine tools and automated production lines. By monitoring pressure parameters in real time, abnormal conditions during equipment operation can be detected promptly, thereby achieving preventive maintenance and enhancing the operational efficiency and reliability of the equipment. In addition, these sensors can also be integrated with industrial automation control systems to achieve precise control of the production process and ensure the stability and consistency of product quality. For instance, in an automated production line, by monitoring the key pressure points of the equipment, potential fault hazards can be detected in a timely manner, maintenance can be carried out in advance, equipment downtime can be reduced, and production efficiency can be enhanced.

四、配套产品推荐Recommended Companion Products

GINS系列熔体压力传感器可与G100智能数字调节仪表配套使用。G100是通用压力或温度输入指示器,具有单或双可配置报警,以及显示过程变量的可线性重传,适用于挤出应用。人性化设计的操作方法,易学易用。仪表允许自编辑操作权限及界面,并可自设密码。全球通用的85 - 265VAC电源或24VDC电源供电、并具备多种面板及外形尺寸供选择。抗干扰性能符合在严酷工业条件下电磁兼容(EMC)的要求。这种配套使用的优势,进一步拓展了GINS系列传感器在不同场景中的应用灵活性,使其能够更好地融入各类自动化控制系统,满足企业多样化的监测与控制需求,实现更高效、精准的生产过程管理。

The GINS series melt pressure sensor can be used in combination with the G100 intelligent digital control instrument.The G100 is a universal pressure or temperature input indicator, featuring single or dual configurable alarms, as well as linear retransmission of process variables for display, making it suitable for extrusion applications. Its user-friendly design is easy to learn and use. The instrument allows for self-editing of operational permissions and interface, and can be password protected. It is powered by a globally compatible 85 - 265VAC or 24VDC power supply, and comes in various panel and form factor options. Its interference resistance meets the requirements for electromagnetic compatibility (EMC) in harsh industrial conditions.This advantage of being used in combination further expands the application flexibility of the GINS series sensors in different scenarios, enabling them to better integrate into various automated control systems, meet the diverse monitoring and control needs of enterprises, and achieve more efficient and precise production process management.

五、总结Summary

GINS系列熔体压力传感器凭借其高精度测量、高稳定性与可靠性、广泛的应用范围、经济与实用的设计、环保与安全特性以及智能化与集成化功能,成为工业生产中不可或缺的测量设备。它不仅能够为塑料挤出、化纤、橡胶、食品、制药、工业自动化等多个领域提供精准的压力监测和控制支持,助力企业优化生产工艺、提高产品质量和生产效率,还能够有效降低企业的设备维护成本和运营风险。选择GINS系列熔体压力传感器,就是选择高效、稳定和可靠的生产过程监控解决方案,为企业的可持续发展提供坚实保障。

The GINS series melt pressure sensors, with their high-precision measurement, high stability and reliability, wide application range, economical and practical design, environmental protection and safety features, as well as intelligent and integrated functions, have become indispensable measuring devices in industrial production. It not only provides precise pressure monitoring and control support for multiple fields such as plastic extrusion, chemical fibers, rubber, food, pharmaceuticals, and industrial automation, helping enterprises optimize production processes, improve product quality and production efficiency, but also effectively reduces equipment maintenance costs and operational risks for enterprises. Choosing the GINS series melt pressure sensor means choosing an efficient, stable and reliable production process monitoring solution, providing a solid guarantee for the sustainable development of enterprises.